Generally speaking, when someone says clean water, we tend to think of drinking water. However, we also need clean water as a byproduct of our wastewater system. When the water is done being used in a factory, or is flushed down a toilet, how does it become clean again, and how do we know the water is actually clean? Conducting a test called Chemical Oxygen Demand can be performed to infer the pollutant levels in a water sample at any water treatment facility.

What is Chemical Oxygen Demand?

Chemical oxygen demand, also known as COD, indirectly measures the organic matter in water samples. COD is regularly performed in wastewater as it is a quicker and more convenient test to perform than biological oxygen demand (BOD). Careful monitoring of COD, and then following up with BOD tests can allow for proactive corrections to the wastewater treatment. Many times, COD testing is a requirement for wastewater treatment plants; and this testing all leads to time and cost savings for the plants.

Application Highlight

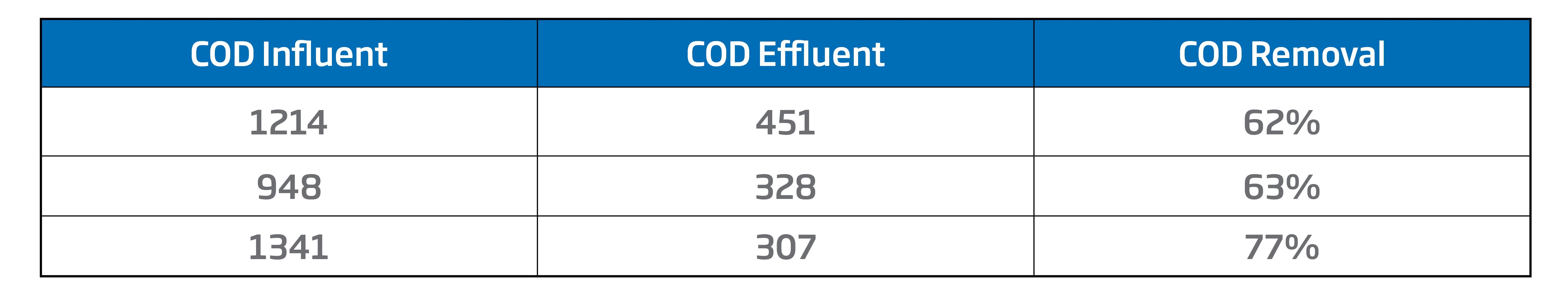

Why worry about measuring organic matter? When it comes to monitoring water treatment, a COD test can clue operators into the amount of pollutants present. COD should be tested in the intake and outtake water to get a snapshot of the efficiency of the wastewater treatment process. COD can also be measured at the plant inlet, the primary clarifier, the aeration tank, and in the secondary clarifier stages. The readings taken are generally quantified as a percentage of pollutant removal, comparing the intake and effluent water measurements. The end goal is to remove as much COD as possible from the system.

Nitrogen and Phosphorus Connection

Monitoring and controlling COD in wastewater is also important in controlling the amount of nitrogen and phosphorus in the waters. COD, nitrogen, and phosphorus levels must abide by environmental regulations, but they are also a great way to minimize plant costs. The more effective the monitoring and control, the lower long-term costs through maintaining the high efficacy of their treatment systems. Total Dissolved Solids (TDS) is used to determine the solid content of a solution. An EC measurement is commonly used to estimate TDS. This assumes that the solids are ionic in nature and the relationship between the dissolved ions and conductivity is known.

How does the COD method work?

Chemical Oxygen Demand is determined by acidifying the water sample, and then heating it to 150˚C for two hours. This heat results in the sample being oxidized. Even with heat, this reaction will not happen spontaneously, it needs a catalyst. Potassium dichromate is regularly used as the oxidant to react with the organic components of the sample. Once the reaction is complete, the chromium can be measured. This is done one of two ways: either by titrimetric analysis or colorimetric analysis. Colorimetric analysis is more commonly used.

For colorimetric analyses, the COD reagents used vary by what standard method the user requires: ISO, EPA, or non-EPA. ISO compliant methods use silver sulfate in the reagents. EPA compliant standard operating methods use mercury in the reagent mix. Non-EPA methods are able to use mercury-free reagents. While disposal of some of the colorimetric reagents can be tricky, colorimetric methods are preferred for wastewater analysis due to the lower reagent needs, and the ease of the sample preparation. Colorimetric methods work very well for a wide range of samples (particularly high range COD samples like wastewater), while titration methods are costlier and more appropriate for low range samples.

So how does this work? The chromium that is added to the sample changes from hexavalent chromium to trivalent chromium. This causes a very distinct color change, where the sample changes from orange to green. The color change allows for the COD concentration to be quantified with a colorimetric reading.

Interferences

While the colorimetric method is very reliable, there are a few things that can interfere with your readings. Anything in your sample that will also reduce the chromium will create a positive interference. Halides (such as chloride) will cause a positive interference as well. If your wastewater sample has an abundance of chloride ions in it, the EPA method is recommended as the mercury in the reagents can help to negate the interference.

Product Spotlight

The HI83399 Water & Wastewater Multiparameter (with COD) Photometer and pH meter, paired with the HI839800 COD Test Tube Heater and COD reagents, is a perfect combination for COD testing. Not only is the meter more compact than those in the past, it also saves benchtop space by allowing for direct pH measurements of samples with a pH electrode. There are 73 pre-programmed methods, with 40 of them being particular to water and wastewater management and analysis. The digestion block is recommended as it will heat and maintain the required temperature for the COD reaction to occur. The slots built into the block are designed to fit the COD tubes that are prefilled with the required (and sometimes hazardous) reagents.

A high efficiency LED is used as the light source in the HI83399, which is an improvement over the previous tungsten lamps. Not only does the LED provide better and more consistent light, it also consumes less power. You no longer have to worry about a “Lamp Cooling” warning interrupting your readings; the LED produces very little heat, and therefore does not have to cool back down during multiple readings.

The improved optical system integrates split beam technology for accuracy and drift correction (due to a reference detector), as well as the added feature of the light being able to be used for absorbance readings. This optical system also includes narrow band interference filters. This allows for a much smaller margin of error by being much more selective when you set the method to a specific wavelength.

The combination of the large cuvette size and a focusing lens, allows the user to no longer have to index the cuvette. Large cuvettes help reduce the errors that can occur when a cuvette is rotated. The focusing lens removes the error associated with imperfections in the cuvette glass.

Let Hanna Help You With your COD Testing

Whether you are measuring COD in a lab, or in the field, we have complete solutions to meet your needs!

That's why we've dedicated our blog as a helpful resource for you to use! Catch up on the latest products, explore industry trends, discover testing tips, learn how to improve results, and more. Got questions? Email sales@hannainst.com.