Scroll down to read the full list, or click the points below to jump to a certain point:

Automatic titration technology is more accessible, easier to use, and more affordable than ever before. Many businesses see 1-2 year payback periods on high performance multi-parameter systems. Single parameter titrators now cost under $1,000. Technology today is making leaps and bounds while affordability is on the rise. Why not make the switch from manual titration to automatic titration?

Technology today is making leaps and bounds while affordability is on the rise. Why not make the switch from manual titration to automatic titration?

Titration continues to be a core analysis across a range of industries. Manual titration is the most common approach; it's fast and easy to do. However, visual inspection and manual dosing means results vary depending on the technician. Analytical standards are rising. Your company and its customers need to be confident that their quality requirements are being met consistently.

Change is hard, though. To help businesses prepare a case for titration, we have compiled a list of our top 5 reasons of why you should move to automated titration.

Titration Basics

First, let's recap how titrations work:

- A solution of known concentration, called the titrant, is added to react with the sample you would like to measure, called the analyte.

- The titrant is added until an endpoint is reached, which signals the end of the titration.

Manual Titration

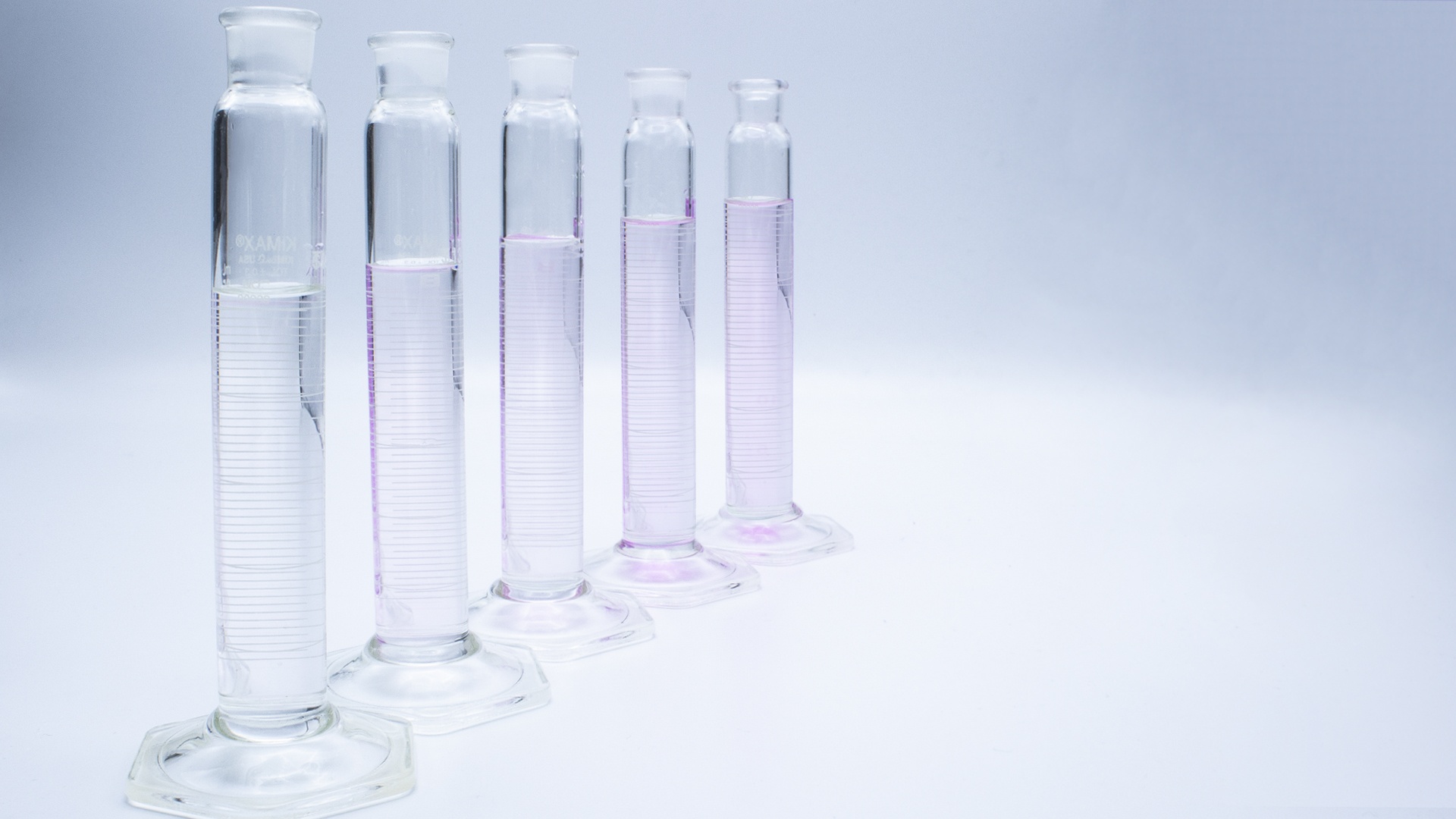

In many manual titrations, a chemical indicator signals the endpoint.

The chemical indicator changes color once the titrant reacts with all of the analyte (i.e. all of the acidity or salt in a food sample). These color changes can be difficult to see, and may be interpreted differently by users.

Example

In an acidity titration, a base such as NaOH is added to a sample.

At the endpoint, phenolphthalein changes from colorless to pink at pH 8.2. However, one person’s idea of pink may be different from another person’s idea of pink, resulting in inconsistent results among lab technicians.

When working with colored samples, like food, detecting this color change becomes even more difficult. The milk sample below has been titrated to pH 6.8 (left) and pH 8.2 (right).

Top 5 Reasons Why You Should Move to Automated Titration

Automatic titration fixes many of the issues with manual methods, and brings new benefits.

Reason #1

Your endpoint is based on data,

not opinion

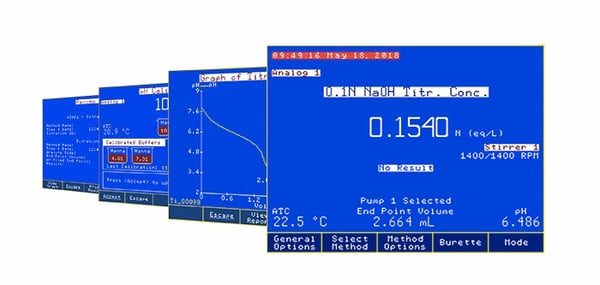

Automatic titrators use sensors as the indicator. These sensors are sensitive to the amount of analyte in your sample.

Example

We use a pH electrode in acidity titrations and a silver billet electrode for salt (NaCl) titrations.

These electrodes work by detecting the voltage change resulting from the chemical reaction at the point where all of the analyte is consumed by the titrant.

The automatic titrator then analyzes the data, and determines the exact volume at the endpoint. This has the advantage of more sensitive, non-subjective endpoint detection, leading to results that are accurate.

Reason #2

You will obtain better accuracy and repeatability

Manual titrations use a glass burette to add the titrant to the sample. A stopcock (a valve that can be manually opened or closed to permit titrant flow) controls the burette’s dosing.

However, the precision of these doses are entirely dependent on the analyst’s skill.

Under ideal conditions, this can produce reasonably accurate results, but is not reliable when comparing results among different users with varying levels of experience.

With automatic titration, a high precision piston-driven pump performs titrant additions. These pumps are capable of doses as small as 0.001mL. This provides greater resolution than would be possible with manual titration.

In addition, since an automatic pump is dosing, the results will not be influenced by an analyst’s skill. Instead, user involvement is limited to:

- Measuring the sample

- Submersing the electrode and titrant dosing tip

- Pressing Start

Each sample is titrated in exactly the same way since the control parameters are preprogrammed.

Reason #3

You can reduce chemical and sample usage

To obtain accurate results, the lower dosing resolution typical of manual titrations is typically offset by a larger sample size. The high titrant volume compensates for the inability for small doses resulting in increased chemical use.

The increased chemical consumption is a big issue especially if the titrant is expensive.

Example

Salt and acidity are common analyses in food. Salt is determined by titration with silver nitrate- an expensive titrant. One liter of 0.1N silver nitrate (the most common concentration for food titrations) costs anywhere from $90-120.00, depending on the supplier.

Automatic titration can significantly reduce titrant consumption without compromising on the precision of the results. Due to the high dosing accuracy, titrations can use smaller sample sizes and as a result, use less titrant.

Hanna Tip: Look for dynamic dosing for highly efficient titrant usage.

The initial startup cost of automatic titration is higher, a major payoff can come in the form of chemical cost savings. The cost of sample wasted can also be an issue. The availability of linked methods in some applications allows two titrations to be completed on one sample.

Reason #4

You will save time and increase productivity in the lab

One of the best benefits of switching to automatic titration is the saving of active bench-time.

Manual titrations require the full attention of the person performing the test, as they are adding titrant and watching for the endpoint. Since the analyst is occupied for the entire duration of the test, he/she cannot perform other tasks until the titration is complete.

When titrations are automated, the user is no longer involved in the titration process once they prepare the sample and start the titrator. While the titration progresses automatically, the user can prepare the next titration sample, run another test, or perform any other job functions. All the user has to do is return to the titrator at completion and obtain the result, just a couple of minutes later.

To realize all the potential time savings, it is often necessary to automate sample handling with an autosampler, allowing higher throughput and longer available time intervals to complete other tasks.

The HI921 Autosampler can automate up to 18 samples per batch when paired with a HI932C.

Reason #5

You gain traceability over your data

Even if a manual titration is performed correctly, the result is not easily traceable due to the lack of a report. Manual reporting is feasible, but can be prone to errors in transcribing and transferring data and is otherwise cumbersome.

Automatic titration systems are capable of generating an automatic report for each titration.

The report is customizable to include results, titration parameters, dose-specific data points, and good laboratory practice (GLP) information. The extensive report offers confidence in the validity of titration data and allows for easy record keeping.

Conclusion

Overall, automatic titration systems provide an easy way to increase throughput, accuracy, traceability and peace of mind in the laboratory or in production.

There is some initial capital investment but this investment may not be as high as you think.

For high volume applications, the savings on time and reagents alone is sufficient to provide a return on the investment for an advanced automatic titration system.

Depending on the system, you could have an advanced automatic titration system for high volume applications up and running for less than $4,500. At less than $1,000, affordable single parameter mini-titrators make automated titration accessible for low-throughput applications.

When working with Hanna Instruments for your automatic titration needs, Hanna provides not only the instrument, reagents, and electrodes, but also, the technical support and training to make sure that you have a smooth transition to automation.

With Hanna Instruments, making the switch to automatic titration is easy.

That's why we've dedicated our blog as a helpful resource for you to use! Catch up on the latest products, explore industry trends, discover testing tips, learn how to improve results, and more. Got questions? Email sales@hannainst.com.